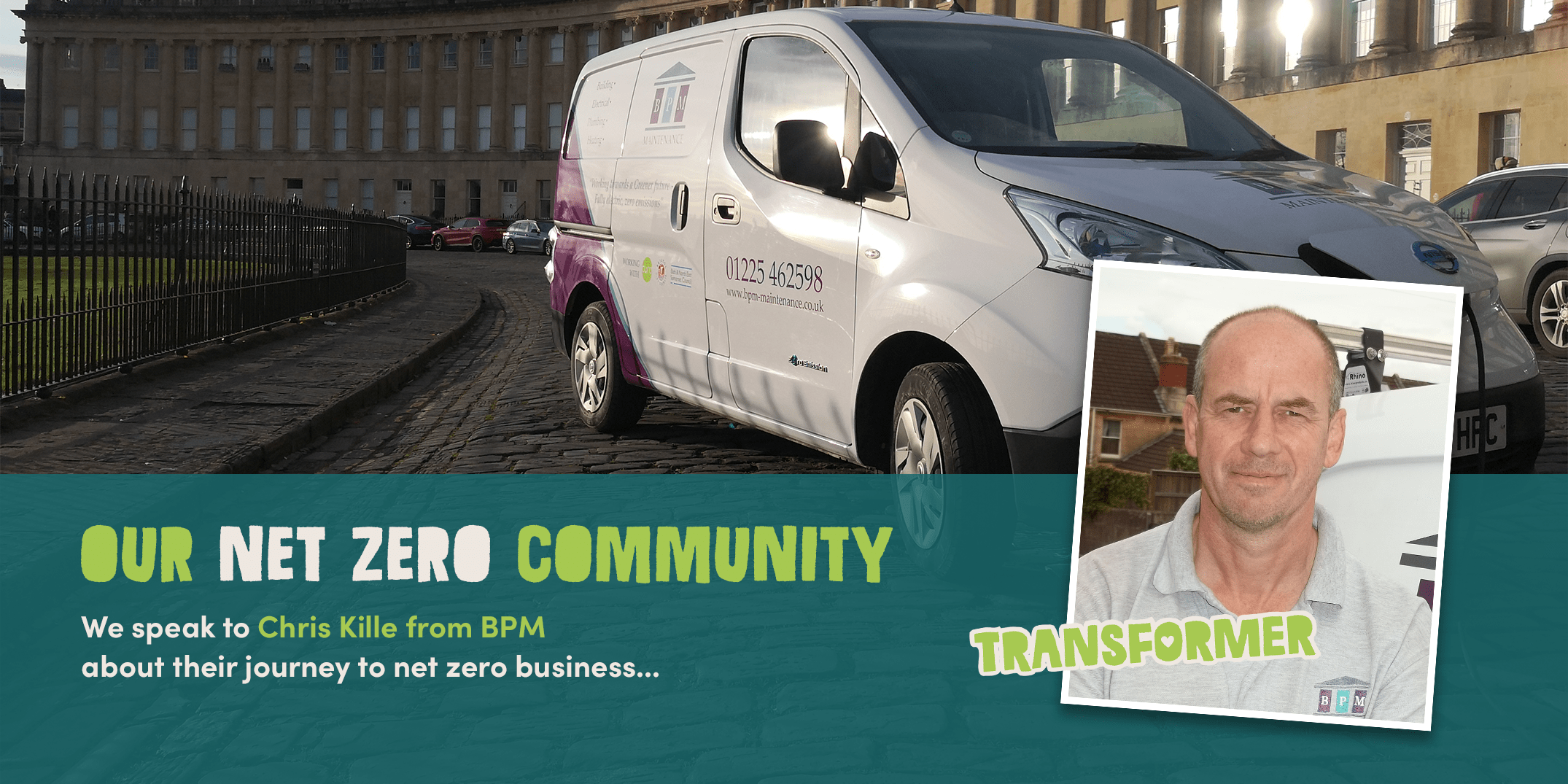

Going net zero with BPM

We speak to Chris Kille from BPM about their journey to net zero business...

Since 2005, BPM Contracting Services has speclialised in building repair and maintenance services. Key clients include BANES, Bristol City Council, Swindon Borough Council, New Forest District Council, Curo Housing, Guinness Housing, Sanctuary Housing and Sovereign Housing. The company is made up of around 50 staff, including 15 apprentices, several graduates and a number of ex-military personnel.

As Managing Director, Chris' role oversees the general running of the business, and he works closely with the senior management team on their overall strategic delivery - including their target of becoming a net zero business.

Chris was born in Bristol, and spent his early years living in Exmoor and London, before returning to his 'spiritual home' of the West of England in 2001. Chris' father was an engineer designing roads, bridges and other building infrastructure, and his grandfather was a carpenter/furniture maker. After running an activities holiday business for 15 years, Chris retrained and set up BPM.

As a business owner, Chris is very aware of the need to incorporate sustainable choices into his everyday life...

"There is a general understanding of the pressing need to address carbon emissions, and as a responsible employer this is the underlying motivation. This driver however is also allied with efficiency, driving innovation and being at the forefront of technology."

BPM is commited to engaging wherever possible to with programmes supporting sustainability. With support from the West of England and Action Net Zero, BPM has been able to measure their carbon footprint, giving the company a base from which to work out where they can improve.

To achieve Net Zero, BPM made a commitment to replace the entirety of their fleet with zero emission electric vehicles.

"12% of our vehicles have been replaced with electric so far, and 93% of the remaining vehicles have been replaced with leased low-emission ULEZ-compliant Euro 6 vehicles, whilst we continue to purchase new electric vans."

These changes have reduced their total vehicular CO2 emissions by ~850kg per month so far, despite 40% growth in company turnover over this period.

Chris and his team have also enrolled in SWMAS’ ‘Make it Net Zero’ Programme to tackle their remaining emissions. To minimise office emissions, they have drawn up plans to build a new 10,000 sqft zero emission office with a modern energy efficient design, using the latest green technology. This includes heat pumps, LED lighting, arrays of solar panels and EV chargers.

Through the programme, they are able to closely monitor their emissions as well as track reductions. Once BPM has achieved every possible measure to reduce emissions, Chris plans to use carbon offsetting to achieve Net Zero.

The changes don't stop there...

"We've introduced recycling bins, and reduced print outs and single-use plastics to improve our waste management. Non-reusable/recyclable waste is disposed of responsibly."

Employees are asked to 'green their commute' where possible; with employees based region-wide, this allows BPM to significantly reduce commutes by deploying the team member closest to a site, helping to reduce the environmental impact of their operations by dramatically reducing vehicle mileage.

Any suppliers are evaluated based on their sustainability practices, and they strive for sustainable procurement, sourcing locally wherever possible. BPM now offer training to equip employees with the knowledge and skills to work in an eco-friendly manner.

"As we retrofit older offices and upgrade facilities, energy efficiency and resource conservation are prioritised."

Chris has made sure that BPM communicate their sustainability goals to all staff, and encourage ideas to reduce emissions and waste. As part of BPM's ISO14001 environmental management system, they hold regular environmental training sessions, which include discussions on improvements they can make a business.

All staff are invited to attend these sessions, to allow BPM to receive a broad range of feedback from the bottom up. They also carry out periodic surveys to collect staff ideas; the feedback received has led to improvements such as more comprehensive waste sorting and improved environmental spill kits.